Keeping Your Serger Clean

Proper maintenance of any machine help keep you from costly repairs. You'll find your serger needs to be cleaned much more frequently than your home sewing machine because they operate at a much higher speed and those internal parts are rotating more often.

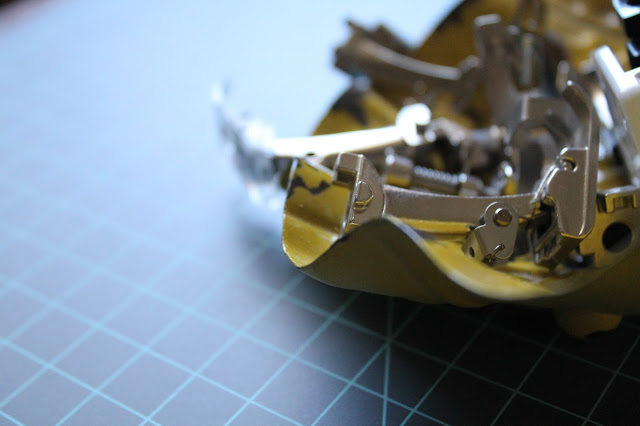

Cleaning & Oiling A Serger

Serger knives create a great deal of lint, which must be cleaned from the machine- try using a dry lint brush for this. In my Serger Tool Kit post, I recommended sourcing a larger sturdy bristle brush to help cover more ground. I also like to keep scraps of batting nearby. As I catch the lint on my brush end, I swipe it onto the batting. The batting helps to keep the small piles of lint in place as I work my way through the machine.

The points of which you must oil your serger will be noted in your machine manual. However, it's important for me to mention to use only sewing machine oil; household oil is too heavy and should not be used. Here's where I oil mine (video)

Typically, you will need to oil your machine every 8 hours of actual serging time (pedal down.) Your serger should run with a smoooooooooth humming sound, if it doesn't it needs oil. Also, any overlocker that has been sitting unused for two months of longer needs to be re-oiled because the oil drains to the bottom of the machine.

Replacing Needles

Serger needles wear out quickly! Needles that are dull, bent, or burred will cause your stitches to form improperly. If you're ever experiencing skipped stitches, uneven stitches, or puckered seams; the first troubleshooting solution is change your needles! I also covered this in an instagram post, but just in case you're not yet following me there (here's another tip!)

Cleaning Tension Discs

Tie several knots of 6" to 10" of a heavy duty thread, soak it in rubbing alcohol (optional.) Work the knotted thread between the tension discs several times to remove lint build up.

We've covered a lot of ground so far this month in the Love Your Serger blog series, including What is a Serger?, How Does A Serger Work?, What to Ask When Buying A Serger?, The Essential Tools You Need For Your Serger, and now we're keeping it clean. Next Monday I'll be posting the first tutorial of the bunch- teaching you how to use your serger to insert zippers! If you're up for the challenge the only thing you'll need is 1 place mat, 1 22'' Nylon zipper, and your serger (with thread!) I hope to see you back here Monday!

Thanks for this series Janelle! I appreciate all that you've posted and I've learned a lot. I just recently recieved an hand-me-down, 30 year old serger that really runs great, but it needed cleaning (badly). I didn't even think about cleaning between the tension discs. That's next on my to-do list.

ReplyDelete